Revolutionizing Material Processing for Industrial Value Creation

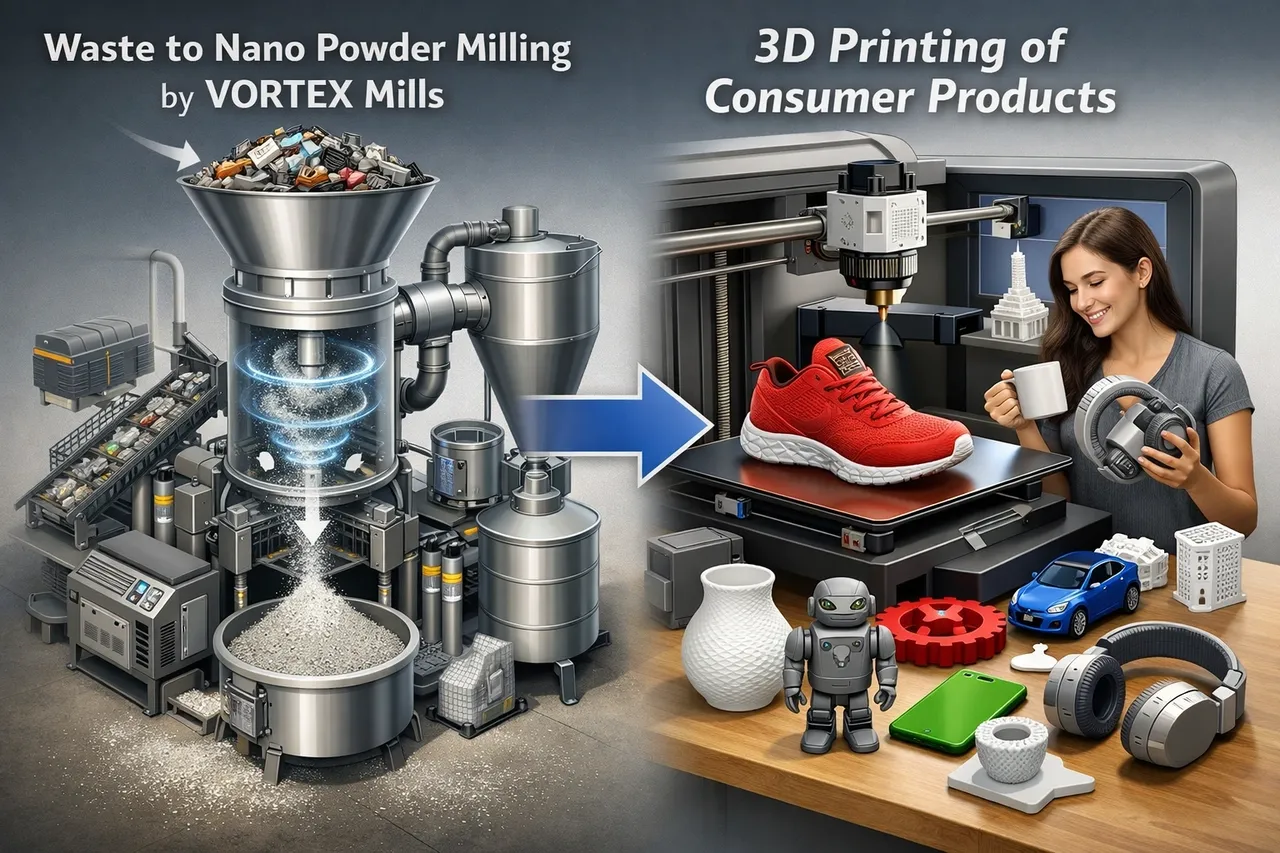

At the heart of the Genesis platform — and a cornerstone of the broader AVIS Umbrella infrastructure — lies the VORTEX Contactless Milling System, a high-impact technology designed to transform how materials are processed and repurposed at industrial scales.

Unlike traditional milling and grinding technologies that rely on mechanical contact, wear parts, and high maintenance, VORTEX leverages controlled vortex plasma dynamics to break down materials at the molecular level. This innovative approach dramatically reduces operational downtime, cuts energy losses, and eliminates consumables, leading to superior lifetime economics and lower total cost of ownership for facility operators.

From an investment perspective, VORTEX technology drives value in three key areas:

- Scalability Across Industries – Applicable to waste conversion, mining, recycling, and raw material preparation, VORTEX can be deployed in modular container units or integrated into large-scale facilities.

- Feedstock Generation for Advanced Manufacturing – The nanopowder output feeds 3D printing and composites industries, creating new revenue streams from previously low-value or waste inputs.

- Sustainability at Scale – By enabling green material cycles and reducing carbon intensity, the technology aligns with investor priorities around ESG impact and durable competitive advantage.